Tech Project

Description of the challenges faced by the Tech Project

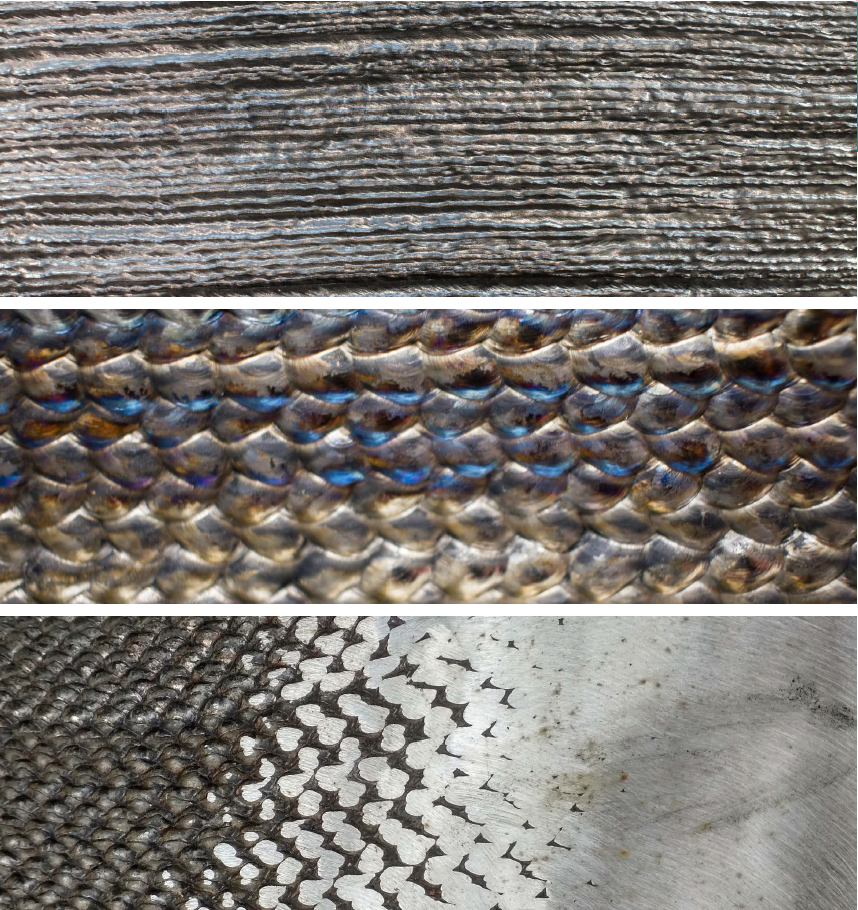

Challenges of the project exist on several levels, here a few: Finding the sweet spot between economic feasibility and added value Although the 3DMP-Technology is one of the fastest additive manufacturing processes, it is still expensive. We believe that additional value for end customers and the creative sector can be created, yet, pivoting the economic and technical constraints against functional and aesthetic advantages is one challenge. Understanding “creatives” The 3DMP-technology was developed for large industrial metal parts, e.g. for ships or airplanes. For these industrial applications the surfaces of the printed part have to be milled in order to function properly. Yet, the unprocessed artisanal surfaces can be used as an artistic feature in creative segments and distinguish it from other technologies. 3DMP-Living is an internal spin-off that aims to unveil and develop economic business cases for large scale metal print in the fields of architecture, art and design. Compared to other 3D metal printing methods the technology is cost efficient and enables the designer to think on a large scale (up to 3 cubic meters) and create real size objects that are sustainable and functional. This lifts 3D-printing from the status of “prototyping” to the status of “production”. Additionally, it is the only additive manufacturing technology which offers the possibility to combine different metals during the print process.

Brief description of technology

3DMP® means 3D Metal Printing. The technology combines the technically mature and highly reliable arc welding method with the CAD data of the metal parts that are to be produced. The interface between the planning data of the engineers and developers, on the one hand, and the arc-welding machine, on the other hand, is our bespoke software that takes the CAD data and converts them into individual digital printing layers, the so-called CAM models. The blank part is printed fully automatically and in a controlled manner. This step is followed by a 3D scan for quality control and finally the milling of the finished part (if necessary).

What the project is looking to gain from the collaboration and what kind of artist would be suitable

Aim of the cooperation is to explore new production processes and the unique aesthetics of the metallic surface with every part. They can be influenced depending on: - process parameters - use of 3 or 5-axes - material combinations Thus, we want to find out if 3DMP has a potential market in creative businesses and opens up completely new opportunities for designer, artists and architects. Our goal is to expand the use of the technology to new fields of products and market segments. An artist who has profound knowledge in CAD or comparable programs is mandatory. First experiences with 3D printing technology and metal processing would be beneficial.

Resources available to the artist

We offer a studio facility in Berlin for all kinds of material experiments, access to our internal workshop and special training in the CAM software and 3DMP technology. We also offer complete integration in the project team for knowledge transfer and function as sparring partner and technical supervisor. We will grant considerable time for artistic production with the prototype machine (3axes). Furthermore we have a 3D plastic printer for all kinds of testing. For the professional machine it is necessary to be handled by experienced staff - according to the artists design. As each machine hour and raw material is quite expensive - testing opportunities will be offered but limited. For the resulting object(s) that should be large scale we will offer production capacity at the professional machines (together with supervised staff) to realize the artist’s design. Companies within the berlin.industrial.group develop high performing technologies, therefore we have various workshops on campus. If beneficial to the project, we could organize quick and uncomplicated access to other machines such a metal laser cutting, CNC milling … within our network.