Tech Project

Description of the challenges faced by the Tech Project

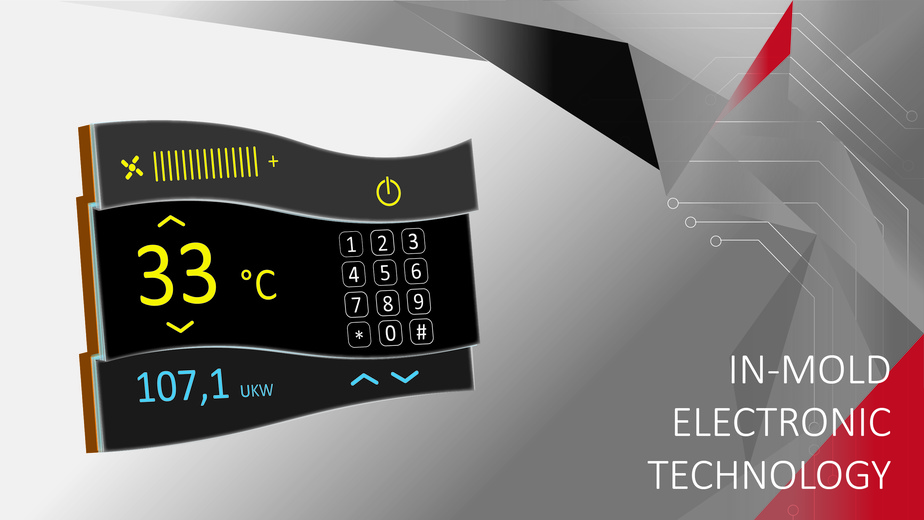

Since we are hosting the artist at the COPT Center, technologies that can be made available to design and produce an artwork are OLEDs with various colors and shapes, as well as 3D printing. This methods allows to design freely the plastic surrounding and finally make the plastic parts. The main challenge is to mesh desired design with functions. From technology perspective, this includes the following questions: How to bring both components together to make decorative, high quality surfaces with functions that actually work (here: light)? Where to put or hide the connection? What about the power supply? How to connect plastic and electrical device? How to protect the OLED being fragile because on glass substrates?

Brief description of technology

At the COPT center we operate the equipment to make thin and surface-light emitting diodes (OLED), printed sensors and actuators as well as solar cells. Our OLEDs come in all imaginable colors and in different shapes. Due to technical restrictions, we need to limit their size to 15 x 15 cm² at present. By default, we are using rigid glass as substrates, but OLED on flexible plastic and glass substrates are currently under investigation, e.g. within the dekOLED project. For the film-insertion process using injection molding, we cooperate with partners. As an alternative, we offer 3D-printing as method to integrate OLED into plastic parts. Our in-house 3D-printer prints several kinds of plastic (differ in color and appearance) and offers a high flexibility when it comes to realize extraordinary designs in combination with our light-emitting panels. We aim for artwork that is inspired by light, color and shape.

What the project is looking to gain from the collaboration and what kind of artist would be suitable

We look for thin, light-weight and robust plastic parts that have lighting areas and controls to enable functions. We are building the technology, but we are looking for a person to join the team that comes with a vision of what kind of shape, color, design, and function are needed to bring a new experience to the user. Therefore, we imagine the artist to work with us to combine plastic and function, inspired by light, color and shape. In dekOLED we target mainly the automotive market. At the end of this artistic project, we expect to have some prototypes of the artwork using the technologies and components resulting from dekOLED by the consortium but enabling prototypes with functions for completely different fields. As the artist being a part of the team we will jointly transfer our technology and his inspiration to excite people with a new user feeling in markets outside automobile, such as furniture, household goods, consumer electronics, textiles and sports.

Resources available to the artist

At COPT Centre, the artist can be hosted in one of the offices. In the labs of COPT, equipment to make OLEDs is available, but cannot be handled by the artist. To make OLEDs, the respective technicians have to work at the machines. 3D printing is available for the artist. Working for the artwork has to fit into free slots in-between work for other projects or customers.