Tech Project

Description of the challenges faced by the Tech Project

With the objective of improving the learning process and training of medical students and professionals, Inova de, create it real, the University of Heidelberg and University of tübingen have started a project to produce realistic and accurate 3d models of a particular patient funded within the framework of the Eurostars programme. To address this problem, the consortium proposes itself to produce the next level of 3D printing services for medical training and education: • 3D printed organ models that are realistic, affordable, conform to the actual patient images and at the hands of every medical student. • These anatomically correct models will have the same haptic characteristics as real organs, enabling a better learning experience.

Brief description of technology

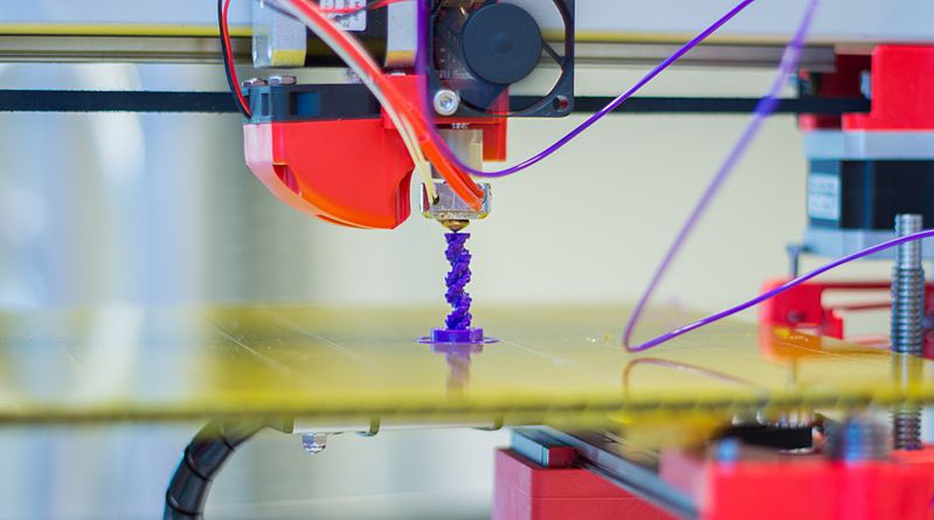

We are developing a new 3D-printing system capable of creating the most sophisticated and realistic human organ models to date. It will allow physicians a realistic and accurate view of the human body, focusing on subtleties such as tissue hardness and fine-structures. How does it work? The student creates a 3D organ model using our software and places the print order. The created model is sent over the internet with all the material choices to us, and the organ is delivered at home. Alternatively third-party 3D modelling software can be used to create models for printing. The hardness profile needed for our innovation can be added posteriorly. We use FDM technology to create the model and evaluate the results. The advantages? This system allows hands-on approach to learning anatomy with pathologies not described in literature or simply not available locally. It allows a better preparation for practical classes, for exams and surgery and thus improving their learning experience and increase their success-rate and grades. Elements available are different materials for 3D printing and modelling software. The new printer head is being developed still, but we can print tests on other equipment.

What the project is looking to gain from the collaboration and what kind of artist would be suitable

The texture feeling between the real and printed organs is a relevant topic to address throughout the project. The example of an artwork, made for people to touch and interact with, would also help us get the feedback of our technical development. Making the artwork interactive with the public, involving the spectator in an engaging way by use of the touch sense - which is often restricted to other art installations – brings new perspectives to the artist as well as us as developers. It is more than a communication and story-telling question; is the way how the art and science have a symbiosis (e.g. the world-famous “Körperwelten” exhibitions). In short, we look for a plastic artist that will print itself to new dimensions of artistic expression and interaction. It will greatly help with look-and-feel (literally), illustrate new ideas or application areas, showing that we’re on vanguard of [medical] technology.

Resources available to the artist

You will be placed in Heidelberg office with access to all the software tools necessary for your work. 3D Printing tests will be possible, either with the new printer or a standardly available one. The artist will be in direct contact with the development team and consortium, with the opportunity to learn about different industry segments. Traveling with the team between the different demonstrators and team meetings will be supported. Public presentations of the artistic results will be made to encourage more people in testing and using the underlying technology, including hands-on interactive exhibitions.