Tech Project

Description of the challenges faced by the Tech Project

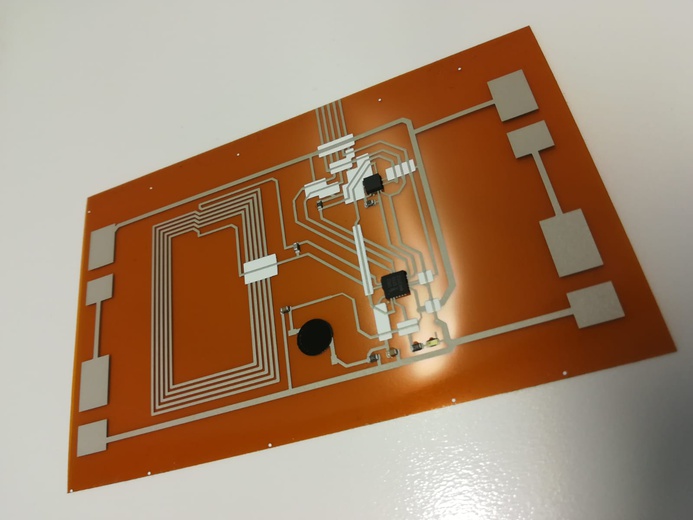

Industrialisation of printed electronics is recently becoming more and more mature. Nonetheless the creative part of printed electronics is lacking. This means that the possibilities to create new functionalities, products etc. is not fully exploited. With the artist the project is seeking for new methods to show the Printed electronics possibilities to the public, enhance dissemination, and be involved in the creative process of making new products. The artist will work with a team of specialists. The artist will be a creative branche seeking for novel applications The team will help in producing samples, and show technilcal possibilities and (possible) limitations

Brief description of technology

Printed electronics is the technology to create electric circuits on a roll using traditional print techniques. The available production capability and functionality maturity for realizing these products in the required numbers is lacking worldwide. Consequently, qualifying materials and manufacturing processes or evaluating products in an operational environment are not accessible to end-users, interested in this technology. In order to facilitate the market introduction of printed electronics devices, production processes need to be ready for large scale pilot production and accessible to all interested parties. In parallel, performance and reliability of product prototypes need to be demonstrated in relevant conditions. The aim of InSCOPE is to advance printed electronics technology to such production prototypes (TRL 7) related to automotive, healthcare, smart packaging and smart buildings. 4 industrial showcases and 15 development cases are created to show the possibilities of Printed electronics. These are Smart lighting wall (for Philips), In-mould electronics dashboard (for Bosch), Smart Elevator (for KONE) and Smart medical packages (for GSK).

What the project is looking to gain from the collaboration and what kind of artist would be suitable

- creative process embedded in printed electronics - novel products - Samples to show printed electronics new functionalities

Resources available to the artist

The artist will be stationed at the Holst Centre owning a desk and access to the lab facilities. The team will assist in production of Printed electronics products. Access to other labs will be facilitated if necessary. The Artist will stay at the Holst Centre for 3 months